Description

Medium bearing TB7

Medium bearing TB7 is a replacement bearing for H10, A10, F5 and F15 template cutters.

The bearings on your template cutters can explode or seize. No problem…prolong the life of your cutter by replacing the small bearing!

Once you’ve replaced your medium bearing, follow the care instructions at the bottom of the page.

Medium bearing TB7 is a replacement bearing for the following Gifkins template cutters:

- H10 template: TGHD 12 ¼ dovetail, and, TGHS 12 ¼ B10 straight.

- A10 template: TGAD 12 ¼ dovetail, and, TGAS 12 ¼ B10 straight.

- F5 template: TGF5 ¼, and finally

- F15 template: TGF15 ¼.

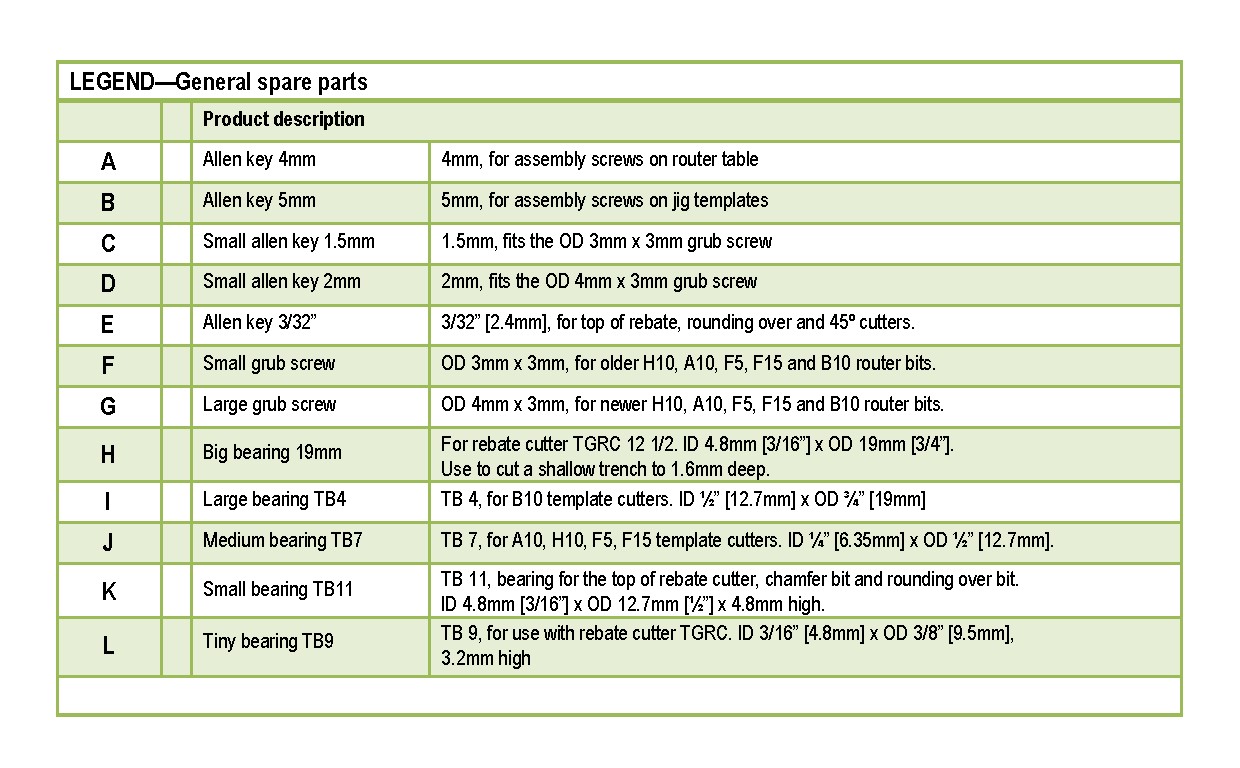

See item J in main image and legend.

Specification: Medium bearing TB7, ID ¼” [6.35mm] x OD ½” [12.7mm]

Please note: postage will be added to your purchase after we receive your order.

Cutter, bearing and collet care:

Prolong the life of your equipment and save money by following these simple steps.

[1] Bearings: Before every box making session, place a drop of sewing machine oil in the bearing to keep it moist. Do not use a drying agent like CRC. The bearing is not sealed, so sawdust and grime build up over time. If you don’t keep the bearing clean, it will seize, causing damage to the cutter and your template.

[2] Cutters: Scrub the cutter blades and the outside surface of the bearing with a toothbrush to remove resin and dirt build-up.

[3] Collet: Clean the router collet in the same way, placing a small drop of oil inside the collet to dissolve resin build-up.

[4] Grub screws: Regularly check that the grub screw in the side of the cutter has not vibrated loose. Alternatively, use a product like ‘Loctite’ to fix the grub screw in place. Hint: to glue in a grub screw, do it over a light coloured cloth on a table. Position the screw hole over the flat edge on the cutter collar. Place a small drop of ‘Loctite’ in the hole and screw in the grub screw.

IMPORTANT—WARNING

All Gifkins Dovetail cutters are designed for use in a table mounted router, and should not be used in a hand held router. We don’t guarantee cutters against breaking. The spiral cutter in particular, has a fine tip and should always be used in the table with a fence.

Take extra care to note the feed direction of the rebate cutter. With all cutting operations, the feed direction is opposite to the direction of motion of the cutting tips (i.e. opposite the direction of the tips as they enter the work piece).

Reviews

There are no reviews yet.